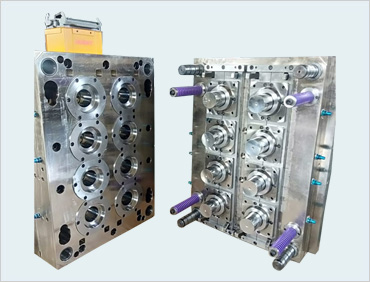

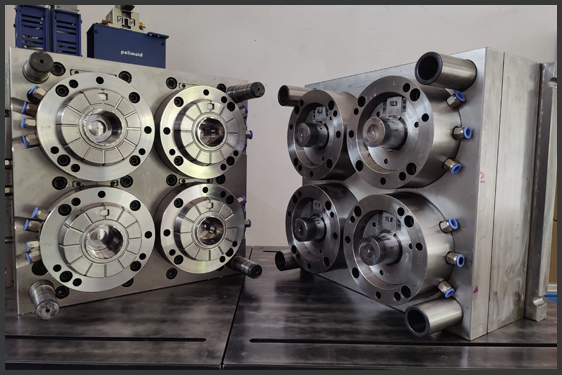

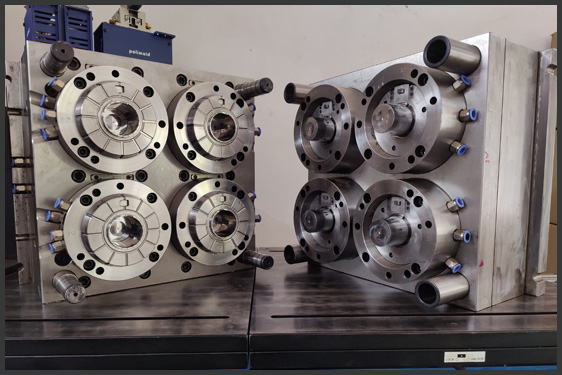

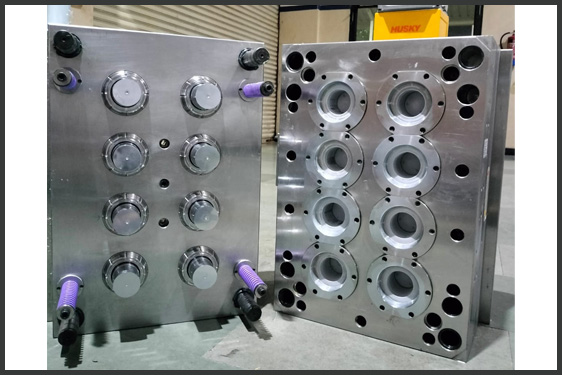

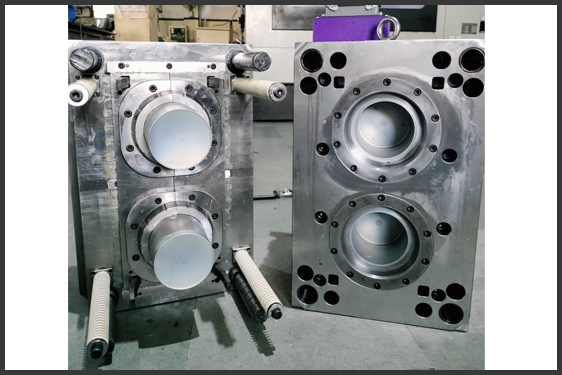

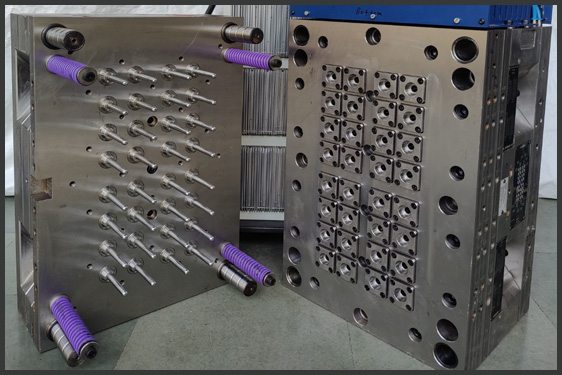

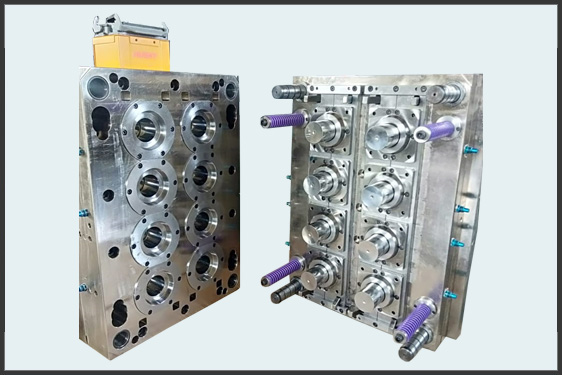

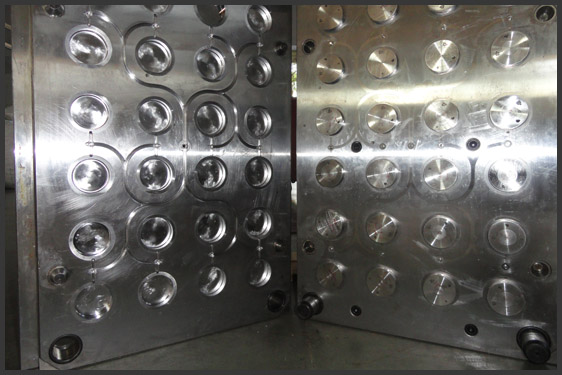

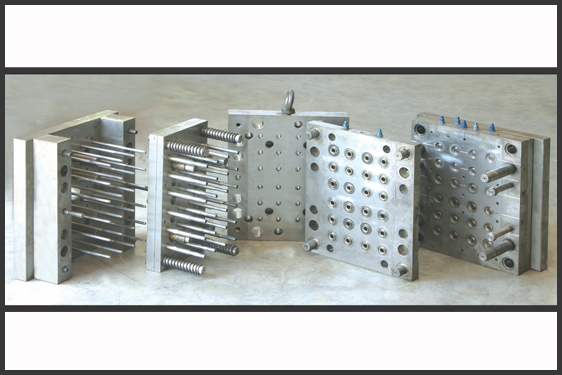

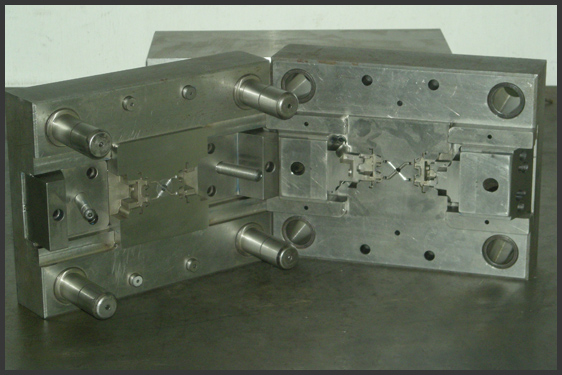

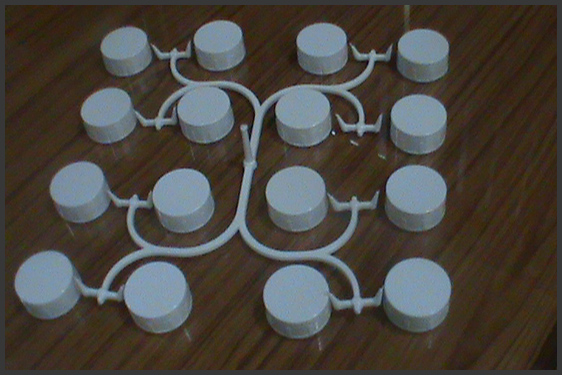

In Injection moulds We make multi-cavity Hardened moulds, ranging from 1 - 96 cavities, with all interchangeable inserts in material - stavax, orvar supreme etc. hardened up to 50/52 hrc.

For Main Plates We use pre-hardened material (P-20, Ramax grade) surface treated (anti- corrosion) for rust prevention. In addition, treatments like nitriding and Pvd coating are offered on inserts to minimise friction and wear in moving parts so that our customers can run the moulds on very low cycle time.